Fancymetal offers high purity (customizable) metal products, as well as oxides, sputtering targets, foils, plates, wires, tubes, rods, powders.

Niobium, with the chemical symbol Nb and atomic number 41, is a transition metal element.

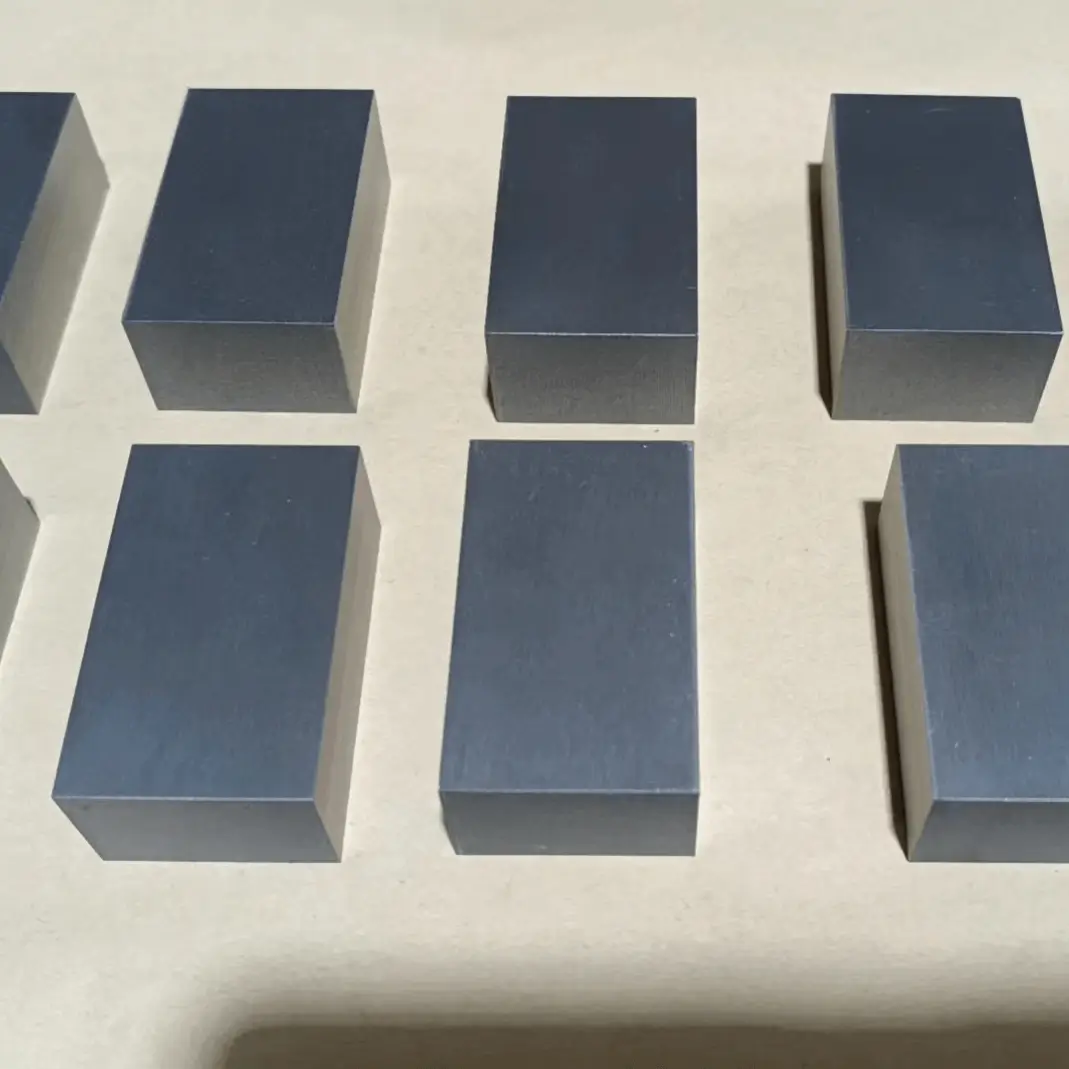

Niobium monomers are a lustrous gray metal.

High-purity niobium metal is ductile, but hardens with increasing impurity content. Niobium has a low capture cross section for thermal neutrons.

Applications:

✔ A direct current generator has been made from niobium-titanium superconductors.

✔ A large part of the world's niobium is used to produce nickel-, chromium- and iron-based high-temperature alloys, either in the pure metal state or as high-purity ferro-niobium and niobium-nickel alloys.

✔ It is used in jet engines, gas turbine engines, rocket components, turbochargers and heat-resistant combustion equipment

✔ C-103 is a niobium alloy containing 89% niobium, 10% hafnium, and 1% titanium that is used in liquid rocket propulsion nozzles, such as the main engine of the Apollo lunar module

✔ Niobium is also important in surgical medicine, where it is used not only to make medical instruments

✔ Of the various microalloying elements in steel, scrap niobium is the most effective microalloying element

Chemical properties:

Room temperature niobium is stable in air, and not completely oxidized when red hot in oxygen, high temperature and sulfur, nitrogen, carbon direct chemistry, can form alloys with titanium, zirconium, hafnium, tungsten. It does not interact with inorganic acids or bases, and is not soluble in aqua regia, but is soluble in hydrofluoric acid.

Niobium metal is extremely stable in air at room temperature and does not interact with air. Although it has a high melting point (2468°C) in its monomeric state

However, its density is lower than that of other refractory metals. Niobium is also resistant to various types of erosion and can form dielectric oxide layers.

Niobium is less electropositive than the element zirconium to its left. Its atoms are almost the same size as those of the element tantalum, which is located below it, due to the contraction effect of the lanthanides.

This makes niobium's chemical properties very similar to those of tantalum. Although its corrosion resistance is not as high as that of Tantalum, it is cheaper and more common, so it is often used as a substitute for Tantalum in less demanding situations, for example as a coating material for chemical tanks in chemical plants.

Advantages:

✔Strict quality control of raw materials and processes

✔Fast delivery time

✔Good service attitude.

✔Technical support: 24 hours via email

HIistory:

In 1864, Christian Wilhelm Blomstrand and Louis Joseph Troos proved that Tantalum and Niobium are two different chemical elements and determined the chemical formulas for a number of related compounds.

The Swiss chemist Jean Charles Galissard de Marigna further proved in 1866 that there were no other elements than Tantalum and Niobium. However, it was not until 1871 that scientists published articles on Ilmenium.

In 1864, de Marigna made the first niobium metal by reducing niobium chloride in hydrogen gas.