Fancymetal offers high purity (customizable) metal products, as well as oxides, product shapes, foils, plates, wires, tubes, rods, powders and a variety of custom shapes.

We also have other antimony products:

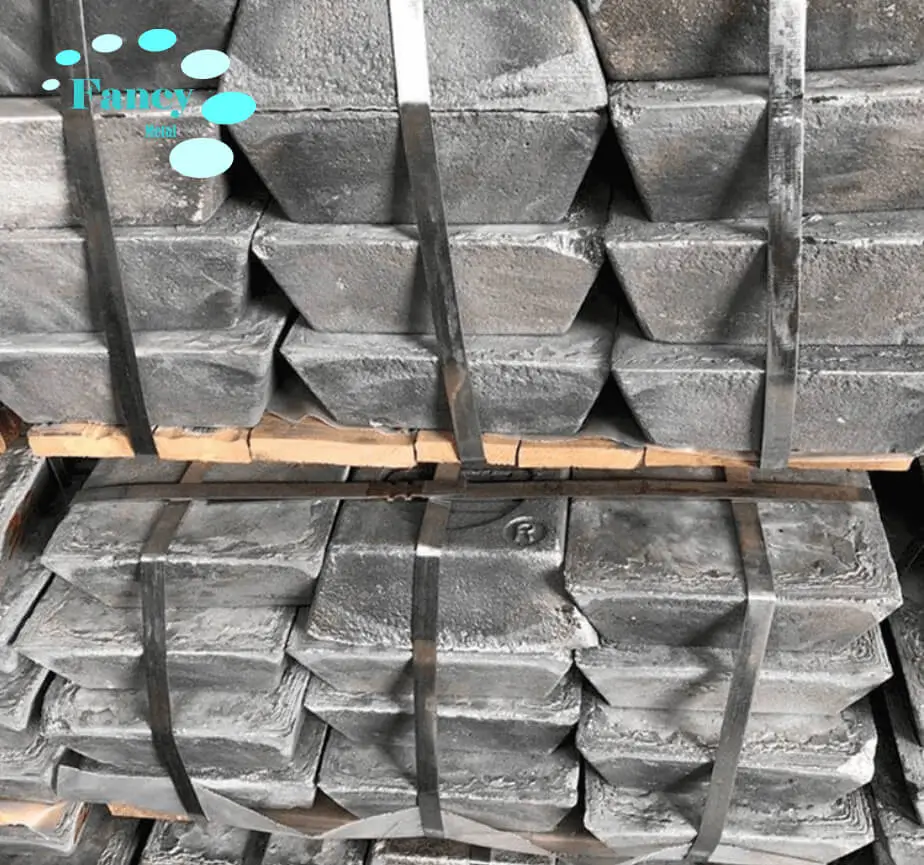

Antimony

Antimony oxide

Antimony target

Antimony Element number is Sb, atomic number is 51, relative atomic mass is 121.76. antimony is a silvery-white, friable, fusible crystalline solid, with poor electrical and thermal conductivity,

which sublimates when heated.

Antimony does not undergo oxidation reaction with oxygen at room temperature, strong heat burns to form white antimony oxide.

Insoluble in water, hydrochloric acid, lye, soluble in aqua regia and hot concentrated sulfuric acid, melting point is 630.5 °C,

boiling point is 1635 °C, relative density (water = 1) is 6.68, antimony's atomic diameter (Goldschmidt's data) for 3.228 A

Applications:

✔ The main role is to increase the hardness, known as the hardening agent of alloys, in the metal after adding varying proportions of antimony, the hardness of the metal will be increased

✔ antimony and alloys with semiconductor properties, wear resistance, flame retardant, is used in semiconductor devices, batteries, wear-resistant alloys, wheel and rail brake pads, pyrotechnics, fireproof materials, etc.

✔ Its oxide antimony trioxide is used in the manufacture of refractory materials.

✔ It forms a versatile alloy with lead, which has improved hardness and mechanical strength compared to antimony

Physical properties:

Antimony has four isotopes, namely grey antimony, black antimony, yellow antimony and blast antimony, the latter three are unstable, grey antimony is the common metallic antimony, silvery-white in appearance, with a purplish-blue metallic sheen on the cross-section.

The Mohs hardness of antimony is 3~3.5, brittle and easy to break, so pure antimony can not be used to make hard objects. The Chinese province of Guizhou once issued coins made of antimony in 1931, but because antimony wears out easily, it was lost heavily in circulation.

Advantages:

✔ Strict quality control of raw materials, process control and pre-delivery processes.

✔ Strong technical capability makes it a reliable long-term supplier.

✔ Technical support: 24 hours technical support by email or phone.

History:

In 1556 G. Agricola, a German metallurgist, described in his work the production of antimony sulphide by fusion of ores, but at that time he mistook antimony sulphide for antimony.

In 1604 the German Valentine (B. Valentine) described the method of extracting antimony and antimony sulphide. 18th century has begun to use the roasting reduction method of antimony refining.

It was not until 1896 that electrolytic antimony was produced.

After 1930, antimony ore smelting in blast furnaces became an important method of producing antimony metal.

In the 1960s and 1970s, various volatile smelting and volatile roasting methods were developed.