Fancymetal offers high purity (customizable) metal products, as well as oxides, sputtering targets, foils, plates, wires, tubes, rods, powders.

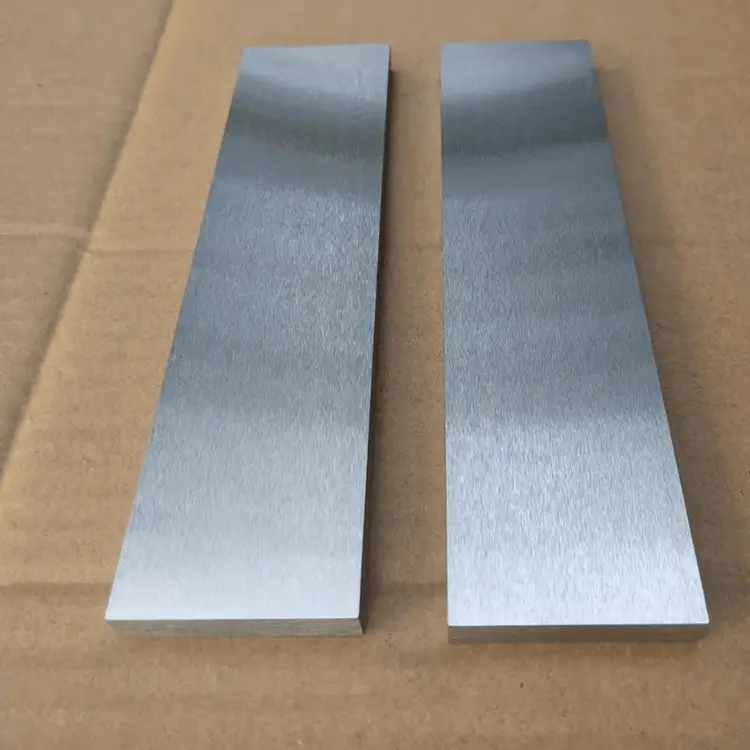

Molybdenum is characterized by high strength, high hardness and excellent mechanical properties, and it maintains its high strength and hardness at high temperatures. Molybdenum is mainly used in steelmaking, and alloy steels doped with molybdenum have high strength, high toughness, outstanding heat-resistant strength and corrosion-resistant properties.

Applications:

✔ Electrodes for melting glass

✔ Heating furnace components

✔ Electrical and electronic components

✔ Casting molds

✔ TZM molybdenum-based alloy has high thermal strength, so it can be used to make molds such as forging dies, stamping dies and punching rods.

Physical Properties:

Molybdenum is a hard, silver-white metal with a cubic crystal system. Relative density is 10.28g/cm³, melting point 2622℃, boiling point 4825℃. Resistivity 5.2X10-⁸Ω-m (20 ℃). Resistant to corrosion due to oxide film on the surface, not oxidized by air at room temperature, insoluble in hydrochloric acid or hydrofluoric acid, soluble in hot concentrated sulfuric acid, nitric acid and molten potassium nitrate. The oxidation states are +2, +4 and +6, with +6 being the main oxidation state.

Advantages:

✔Strict quality control of raw materials and processes

✔Fast delivery time

✔Good service attitude.

✔Technical support: 24 hours via email

History:

In 1778, Scherrer organized a study of a mineral called pyromolybdenite.

In 1782, Elm, a Swedish mine owner, isolated molybdenum metal from molybdenite by burning a mixture of charcoal and molybdic acid seasoned with linseed oil in a closed chamber, naming it molybdenum.

It was named molybdenum, and the elemental symbol was designated as Mo, recognized by Betsy Rius and others.